An artificial intelligence robot designed in Abu Dhabi is revolutionizing the strawberry harvesting process. Created by experts from the Mohamed Bin Zayed University of Artificial Intelligence (MBZUAI), this robot is capable of identifying and picking ripe strawberries without causing damage, whether in sunny fields or controlled greenhouse environments.

The “Strawberry Picker” project is led by the robotics department at MBZUAI, in collaboration with specialists in machine learning and computer vision. The initiative aims to assist farmers in reducing labor costs while maintaining productivity and fruit quality.

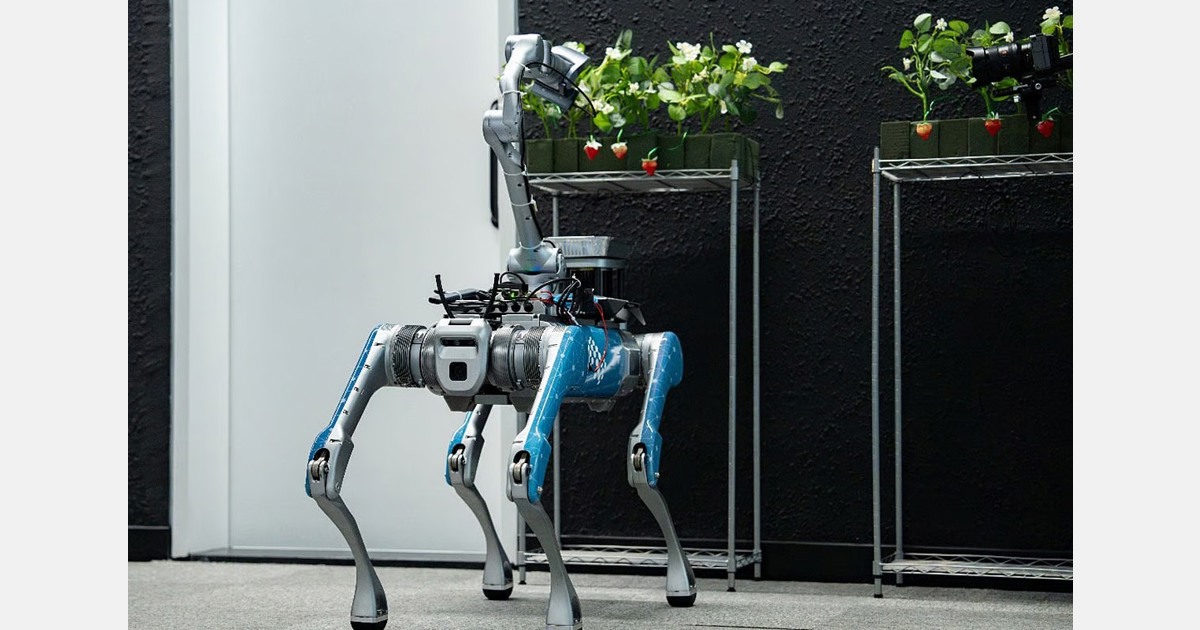

This robot employs advanced technologies in artificial intelligence, computer vision, machine learning, robotics, and precision agriculture. It is equipped with high-resolution cameras and sensors that analyze plants in real time, identifying ripe strawberries based on their color, size, and shape. Machine learning algorithms ensure accurate identification by differentiating mature fruits from those that are unripe or damaged.

Once a ripe strawberry is detected, a robotic arm with a sensitive gripper picks the fruit without causing injury. The robot combines “active perception” with manipulation capabilities, adjusting its position or grip based on environmental factors such as light, obstacles, or plant movements caused by wind. Its autonomous navigation allows the robot to move efficiently through plant rows, optimizing its route and avoiding obstacles with AI-powered pathfinding algorithms.

Professor Dezhen Song, the deputy director of the robotics department at MBZUAI, emphasized that the university’s expertise in robotics, computer vision, and machine learning ensures these robots operate with remarkable precision and adaptability. He noted that they can replicate the care and attention of human workers but do so at a faster and more efficient pace, as reported by Gulf News.

Key contributors to the project include Professors Ivan Laptev and Hao Li, along with a multidisciplinary team of artificial intelligence engineers, roboticists, and agronomists. They address challenges in precision agriculture, which offers numerous advantages over traditional farming methods.

The AI-driven robot enhances accuracy, reduces waste, minimizes damage to plants, and increases crop yields. It operates continuously, providing consistent performance without the need for overtime. Automation helps lower labor costs and address workforce shortages. Its modular design allows for adaptation to various crops, making it scalable for different agricultural environments.

The robot can also be tailored for other crops such as tomatoes, apples, or peppers. Professor Song explained that its advanced sensors enable the robot to adjust to varying lighting conditions, whether bright sunlight or low indoor light in greenhouses. The hardware is built to withstand environmental challenges, including temperature fluctuations, humidity, and dust. AI models can be customized for specific environments, ensuring optimal performance in outdoor fields, indoor vertical farms, or multi-crop greenhouses.

Leave a Reply